Table of Content

Industrial Internet of Things (IIoT), M2M communications, and embracing Industry 4.0 with open arms are vital requirements for industrial organizations to gain a competitive edge and establish secure and scalable products and processes faster.

Every industrial automation operation needs to regulate and maintain the interoperability standard, protocols, and specifications for data communication. In that case, what do you rely on? Sure, you want options that are compatible with IoT.

Interaction between hardware, software, and servers is of utmost importance. You need protocols that offer you uninterrupted communication with your industrial systems. That is where OPC UA, a data exchange standard for machine-to-machine or PC-to-machine communication, comes in handy.

On the other hand, MQTT, which is a lightweight open messaging protocol, offers a resource-constrained network to distribute telemetry information in poor-network environments. But which one is a better option? In this article, we will study both terminologies in detail and find out:

What is OPC UA?

OPC Unified Architecture or OPC UA is an extensible, platform-independent standard enabling the secure exchange of information in industrial systems. It was released by the Open Platform Communications (OPC) Foundation in 2008.

OPC UA is compatible with macOS, Windows, Android, and Linux. It can also be used in embedded systems and bare machines that do not use an operating system. OPC UA works on cloud-based infrastructures, PCs, micro-controllers, and Cyber-Physical Systems (CPS).

OPC UA has many specifications, including Security Model, Overview and Concepts, Information Model, Address Space Model, Data Access, Historical Access, Alarms and Conditions, Discovery and Global Services, Alias Names, Aggregates, and PubSub.

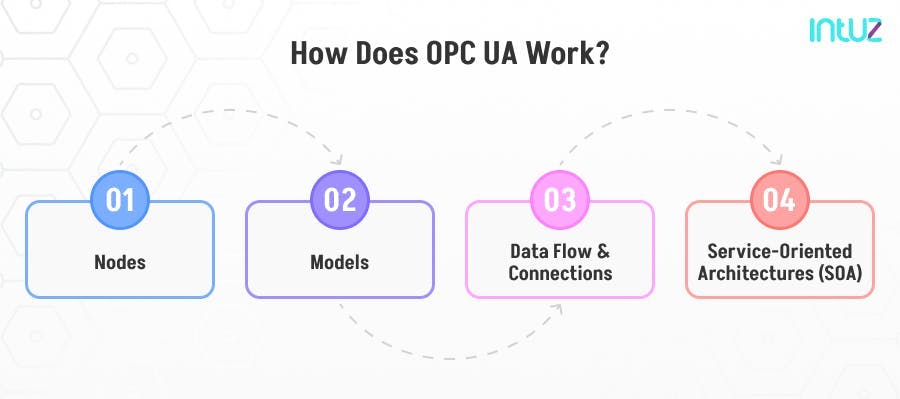

How does OPC UA work?

OPC UA aims to enhance interoperability between hardware devices, automation software, and enterprise planner by offering a framework for industrial companies to intersect contrasting technologies. It makes use of the following components to function:

1. Nodes

A node is the basic data unit in the OPC UA address space, offering a standard for OPC UA server operations. Nodes are information pieces - for example, a unique temperature - comprising attributes, one or more references to other nodes, and the actual data value, each in its own address space. This unique temperature will take up multiple addresses in the address space.

2. Models

Using models, OPC UA defines fundamental rules for putting forth data to any app or device that wants to make use of it. Because OPC UA is itself an information-centric data model, it is made up of a generic object model with a protractile type system with built-in models for data access. In OPC UA, data can be accessed through custom models used in various industries, including robotics engineering and injection molding machine manufacturing.

3. Data flow and connections

OPC UA handles communications between components on five levels in industrial organizations - management, enterprise, control, operations, and field. It enables the transport of information (that devices expose) over a network using standard web services. Data is transmitted using IP-based protocols and SOAP.

4. Service-Oriented Architecture (SOA)

OPC UA is based on the SOA client-server communication framework, which comprises clients and servers like a typical framework. An OPC UA server offers the clients applications and control systems.

Its information models specify how the data is organized, stored, and collected through secure access to industrial automation. On the other hand, OPC UA clients request data from and write data to components in a system through the servers.

What are the use cases of OPC UA?

As discussed before, OPC UA has found popularity amongst industrial systems - from oil and gas to medical and pharmaceutical to agriculture and IoT devices. Common OPC UA apps include asset management, device diagnostics, data integration, data acquisition, and so on. Let us take a look at its top use cases:

1. Efficient support to IIoT

OPC UA is used to push data from embedded devices such as temperature sensors to the cloud to analyze usage and equipment efficiency.

OPC UA’s use of objects to retrieve data effectively allows systems to fetch small amounts of context-specific data for remote workers as they need it for a specific job. In addition, objects may be queried to check out all the data sets for the plant’s operations.

2. Set IoT protocols during cyberattacks

OPC UA events management protocols can automatically shut down a plant if there is a cyberattack on the field devices. It can isolate affected networks and allow limited access to specific networks during this time to enable business continuity until the attack is investigated. It offers strength to industrial security apps.

3. Uninterrupted operations in remote areas

OPC UA can synchronize devices at remote locations. Through resource planning and manufacturing control systems, it can ensure vertical data exchange between high-level applications and heterogeneous drivers.

4. Shorter product development lifecycle

OPC UA ensures highly effective use of resources and automated processes for building complicated products that can self-manage. To enable cost-effective automation on the factory floor, companies must have centralized monitoring and control information hubs that can analyze real-time data and put together methodical processes.

What are the advantages of OPC UA?

Now that you have gone through the use cases, it must be clear that OPC UA has many benefits. Let us dig deeper and check out the top five advantages of OPC UA:

1. Discovery

OPC UA offers plug-and-play capability. When new suppliers are brought to the table or remote plants are added to the business, it can automatically discover their networks, configure them, and merge them within the company network.

2. Scalability

One thing is for sure - OPC UA is future-proof because it empowers businesses to build scalable SCADA systems so that the existing plant equipment can be integrated with new software modules by configuring additional components into the system.

In the oil and gas industry, one can collect the data from calibration, metering, and flow meter sensors remotely, thus freeing up the site inspectors or stakeholders from physically checking the deployment.

3. Interoperability

In simple words, interoperability is defined as a trait of a system or product to work with other systems or products. OPC UA equips end-users with devices and software from different vendors for developing custom industrial systems. It has high interoperability.

4. Decentralization

Traditionally, the automation pyramid in industrial systems defines the information flow from low-level devices such as sensors, meters, or controllers to high-level ERP products. Look at it this way - control flow is the opposite - from low-level devices to high-level ERP products.

These low-level elements are connected through HMIs and PLCs via MES networks. OPC UA facilitates using more flexible data modeling structures in a mesh network. It achieves the same by determining consistent data structures that all components can use easily and conveniently.

Through this arrangement, a field sensor and an ERP product can use the same data model - as an example. Fetching raw data from a broader range of real-time, historical, and event data sources is possible.

5. Platform-independence

Unless you have been living under a rock, you will know that industrial systems used to run on a Windows-based solution. OPC UA is platform-agnostic; it can integrate software from any third-party vendor utilizing any operating system.

OPC UA can be deployed on embedded systems and in the cloud. Its uniform interfaces make it easy to access various apps such as SAP, MES, ERP systems, databases, and cloud platforms.

IoT Protocols: Making IoT Data Communication Seamless

Learn MoreWhat are the disadvantages of OPC UA?

Despite the use cases and benefits, there are certain limitations of OPC UA, in general:

1. Device-specific limitations

Many software manufacturers have highlighted the device-specific disadvantages of OPC UA. For instance, the components used in the company’s software automation products do not offer Enhanced Failover, Electronic Signature, and historical data sources.

2. Complex configuration

In the real world, OPC UA typically manages the data exchange between low-level devices and between SCADA information systems and MES. It is best suited for purposes like systems monitoring and reporting.

However, despite being able to manage interoperability between heterogeneous devices, it is criticized for being rigid and not properly handling various data structures from multiple vendors. This ultimately complicates the deployment process.

OPC UA determines how information in industrial systems is to be exchanged. On the other hand, vendors and organizations decide which data will be exchanged.

This applies to M2M information exchange, machine-to-application information exchange, and the exchange of information at the control level.

In the next section, we will look at an IoT communication protocol called MQTT. Let us find out how different it compares to OPC UA and what benefits and uses it brings to the table.

What is MQTT?

MQTT stands for Message Query Telemetry Transport or MQTT. It is a publish-subscribe protocol that enables brokers to mediate one-to-many communication amongst IoT platforms. That means clients can publish messages to a broker and/or subscribe to one to receive specific notifications.

IBM and Eurotech developed MQTT in 1999 to link oil pipeline sensors to satellites. Today, we use v3.1.1. - the third version of MQTT ensures an easy data exchange within a device network.

MQTT typically transmits messages across devices using limited network bandwidth and a small code footprint. Because of the two benefits, MQTT has paved the way for itself in many industry verticals, including automotive, manufacturing, and oil and gas.

How does MQTT work?

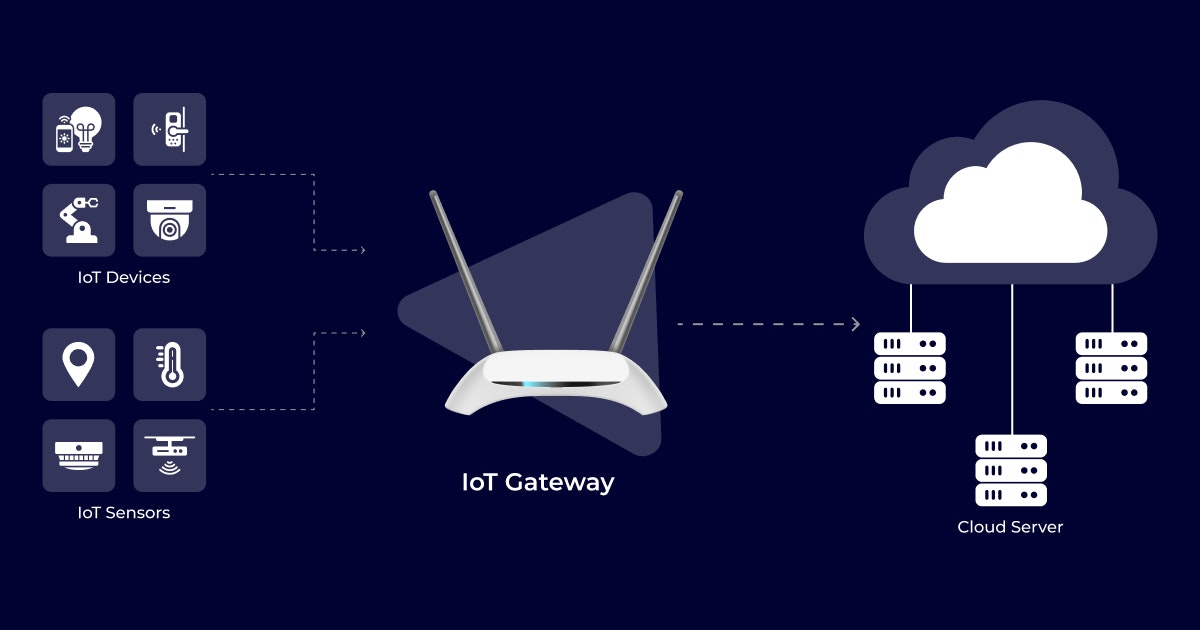

MQTT allows edge-of-network devices for publishing to a broker. Clients connect to this broker, mediating communication between the two devices. Each device can subscribe or register to specific topics. When another client publishes a message on a subscribed topic, the broker forwards the message to any client subscribed.

MQTT is bi-directional and has stateful session awareness. The efficiency and lightweightedness of MQTT considerably increase the amount of data being controlled or monitored. Before MQTT entered the picture, almost 80% of the data was left at remote locations, disabling businesses to make smarter decisions using the data.

Now MQTT collects, transmits, and analyzes more of the data collected. Its publish/subscribe model maximizes the available data bandwidth.

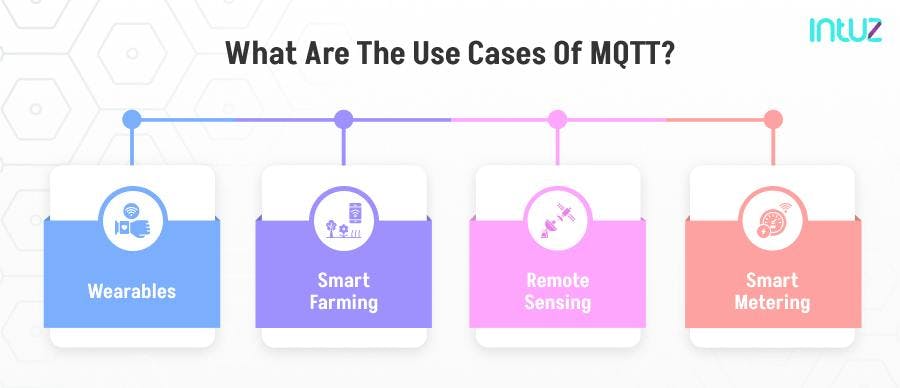

What are the use cases of MQTT?

MQTT is one of the popular IoT protocol and carved a niche for itself in processing plants, smart homes, digital health, and other business niches, serving different purposes.

Some commonly used MQTT-support platforms built for IIoT include Fogwing, IBM Watson, Braincube, AWS IoT, and ThingWorx. These offer MQTT extensions for enabling infrastructure connectivity. Let us study the best use cases of MQTT:

1. Remote sensing

The sensors used in remote monitoring environments often require low power to function from locations or areas with a poor internet connection. MQTT is an excellent option because it enables the communication between devices with lower-priority data transmission requirements.

2. Smart metering

MQTT has found its place in the energy and utility sector. Smart meters, for instance, can collect more detail about energy consumption than traditional meters. That is because an MQTT client can be embedded in the solution deployed with the meter.

This can be used for exchanging data with the guaranteed message delivery system without any lapses in time. The arrangement also allows homeowners to manage energy consumption on their end effectively and make billing/invoicing more accurate because of the data.

3. Smart farming

Using smart technology by agri-businesses can enhance their efficiency and boost the overall yield. You see - innovative farming solutions consistently monitor and report weather and soil conditions, such as air quality, moisture, pH, and temperature. MQTT enables IoT sensors to collect data easily even when the internet connection is faulty.

4. Wearables

Because the MQTT protocol is so lightweight, it can operate on a limited internet connection and poor battery or power. Data gets published only when it is pushed from the wearable to the server, and the receiving devices subscribe to the data pushed. Messages transmit quickly because of the smaller size of the data sets.

MQTT vs. AMQP: IoT Protocols You Must Know About

Learn MoreWhat are the advantages of MQTT?

It is essential to understand how an MQTT broker aggregates data streams and distributes them safely across a complex network to ensure the successful deployment of IoT projects of any size or nature and keep them consistent. Here are the top MQTT pros:

1. The MQTT protocol is highly scalable and can easily connect up to a million IoT sensors and devices.

2. MQTT takes care of the problem of unreliable cellular networks over which IoT gadgets and systems connect to a great extent. It minimizes the time spent reconnecting the client with the broker and supports consistent sessions.

3. MQTT enables messaging flow from cloud-to-device and device-to-cloud models, simplifying the process of broadcasting messages to a group of IoT devices.

4. MQTT takes pride in having a professional and reliable message delivery system, which is much preferred in almost all IoT use cases. MQTT also has specific Quality of Service levels.

5. MQTT clients are lightweight, can be used on small microcontrollers, and optimize network bandwidth efficiently.

6. MQTT has a straightforward message encryption message using TLS and client authentication that uses modern protocols such as OAuth.

What are the disadvantages of MQTT?

Flip a coin, and you know you can choose either of the two sides. Just like that, MQTT brings its cons to the table, which you must be aware of:

1. There is a lack of security encryption as MQTT utilizes unencrypted Secure Sockets Layer or Transport Layer Security (SSL/TLS).

2. The deployment of MQTT is a costly affair. In addition, there is no multicasting support for MQTT.

3. MQTT operates on a flexible topic subscription system, which is not a stable option for resource discovery.

4. MQTT has slower transmit cycles, which means it will not work for you if you want to run an ecosystem with 250+ devices.

5. It is difficult to build a globally scalable network. But it becomes even more challenging with MQTT compared to its competitors.

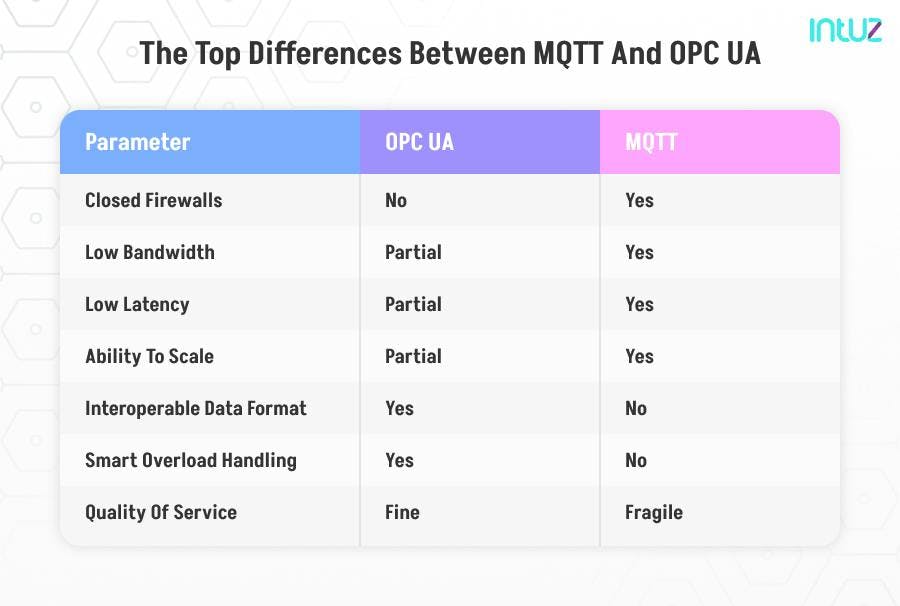

The top differences between MQTT and OPC UA

Now that we have studied both OPC UA and MQTT in detail let us look at a tabular representation of their differences. How different are they from each other?

Over to you

Ultimately, choosing between MQTT and UPC UA is not fair because each protocol has its own pros and cons, fulfilling specific industrial use cases. That is why it is important to carefully architect your network and IoT systems accordingly.

If you are looking for an expert who can explain the differences and benefits of OPC UA and MQTT or simply want to create an IoT project, contact us easily.