As the world population continues to soar, there is increased pressure on the mining industry. Why, do you ask? Because it is an industry currently combating several adverse global trends such as skilled labor shortages, falling commodity prices, and a slowing global economy.

Moreover, 3.11 million pounds of minerals, fuel, and metal are required for consumption by each person in their lifetime.

Given mining is the most labor-intensive and risk-prone activity, there is an immediate need for the industry to deploy advanced technologies to support mission-critical applications in coal mines. That is where the Internet of Things (or IoT) can make all the difference!

The IoT technology brings to the table a much-required digital revolution to change the way mining happens. It implements a cost-efficient approach to improve the industry's overall performance by utilizing several innovative devices.

That includes advanced sensors and wearables that generate a massive amount of raw and real-time data analyzed in real-time and translated into recommendable actions for equipment operators.

The Internet of Things in the mining industry proves to be highly efficient — a complete boon for workers who previously relied on traditional gimmicks. The IoT technology addresses all their pain points and offers relevant solutions in the most effective manner possible.

IoT is the future for mining companies

The Internet of Things technology is highly disruptive as it is affordable and leverages advanced sensor technologies, edge computing, various connectivity networks, Big Data technology platforms, raw data processing and interactive visualization, and critical data science.

The Internet of Things minimizes wastage, ensures accuracy in risk and real-time data analysis, and helps reach an informed decision. Mining automation is the need of the hour!

The technology also addresses one of the most challenging aspects of the mining industry: the safety of the workers in the dark pit of the mines. Real-time tracking and visualization ensure that workers are safe and secure and that there are zero to minor instances of theft.

Some of the other advantages of deploying the Internet of Things in mining are predictive analysis in equipment malfunctioning and landslides and raw data-based utilization of fuel.

How cellular IoT is transforming the mining industry

Cellular IoT is leading the digital transformation in the mining industry, or as some people like to call it — the fourth industrial revolution (Industry 4.0) — with automation, remote visibility, telemetry, and wireless communication.

Mining is an industry where communication is the key, and any gap could be disastrous for business and human lives. Cellular Internet of Things (IoT) ensures cost optimization, efficient communication in mining operations, and high revenues while keeping the worker's safety intact.

Many mining companies and governments are now implementing cellular IoT for planning, deploying, and enhancing real-time data performance. They use the technology for accurate monitoring and analysis of raw data to make an informed business strategy.

Integrate IoT to Automate Your Mining Operations!

Let's Get StartedWhat is trending in the mining industry?

Given the benefits that IoT brings to the fore, it is natural to see how many mining companies have increased their investment after deploying IoT-enabled solutions in their businesses.

Market research shows that mining companies have registered average cost savings of 1.76% in 2018 _ thus proving that cost optimization is a big benefit of mining automation. This is expected to rise to 16.02% in 2023. This excellent ROI is the outcome of implementing IoT technologies in mining over the years.

Benefits of utilizing the IoT technology in the mining industry

IoT makes the mining exercise convenient and organized. The Internet of Things technology supports sensors that accumulate critical data, analyze them in real-time, and share the most suitable action to be taken for a mining operation. IoT enhances worker productivity and makes their performance better. Mentioned below are four benefits of utilizing the IoT technology in the mining industry:

1. Improved safety during mining operations

Installed sensors predict system malfunction and instability in shafts because they pick up real-time data and predict the faulty equipment/where issues may occur.

This information helps in maintaining and preventing any mishaps that may traditionally occur due to the lack of knowledge or resource extraction.

In addition, IoT-based automated machines such as self-driving vehicles provide critical data about the lands being mined. Large mining companies use this data to plan and execute their operations safely.

Thus, Internet of Things saves time, human lives, the company's overhead expenses and ensures smooth project execution with tech-based safety enhancements and resource extraction.

2. Automated mining processes

When vehicles and equipment work together, more data gets gathered, which, in turn, improves accuracy rates. The technology helps the mining companies to filter the data and look at the critical facts, thus ensuring intelligent planning. The Internet of Things-enabled products and their latest upgrades make the mining cycle work faster and be more lucrative.

3. Predictive analytics for a proactive approach

Large mining companies make balanced and informed decisions thanks to data-based prediction. Sensors monitor everything, and the IoT-integrated systems ensure open communication within the environment, enabling a productive scenario.

Having a fully integrated network helps detect wear and tear on essential equipment pieces and the projections concerning when repairs or maintenance are required. This eliminates risk, reduces downtime, and minimizes costs.

4. Higher cost-efficiency and energy savings

An Internet of Things system with mining safety measures intact ensures better efficiency. You see, IoT-based technologies enable holistic growth in productivity of the mining workers, which subsequently optimizes the use of energy and the budget.

Thanks to the Internet of Things, companies worldwide are experiencing a reduction in accidents, employee grievances, minimum human error, and so on. On the other hand, the cost savings can be used for business expansion and the saved energy to contribute towards a greener tomorrow.

5. More time saving

When it comes to creating and maintaining a mine site, IoT helps a lot. The data collected before the digging begins ensures the efficient process is managed properly and with little risk or hassle.

Some of the large mining companies already use driverless vehicles and experiment with autonomous drilling systems to operate without human intervention. This allows the products to be extracted and processed in shorter time frames.

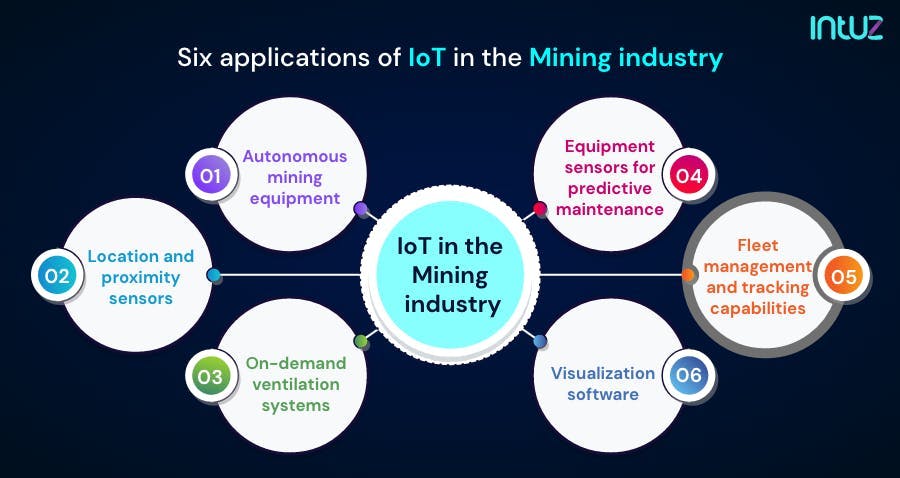

Six applications of IoT in mining industry

IoT-enabled technologies are fast evolving, and there will be many changes in the future that will change the course of history in the mining industry. The essence of the IoT lies in data, analytics, and connectivity. The operations of many mining companies span from port to pit.

They make use of heavy machinery and rely a lot on workers who either spend time underground or in air-conditioned offices. The mining industry is going through a transition, inspiring space and efficient process to watch out for.

In the following section, we will discuss how IoT is bringing fundamental changes to the world of mining through control systems, making it much more safe and productive.

1. Autonomous mining equipment

IoT-enabled autonomous equipment and vehicles have made mining safer and cost-efficient. These machines save workers from getting in harm's way by operating the machinery and self-driving trucks remotely through a high-bandwidth internet connection from miles away.

Such vehicles can navigate routes through a mine and respond to all the conditions they encounter. Self-driving vehicles include:

- Self-driving trains

- Teleoperated bulldozers

- Teleoperated excavators

- Remote-controlled bulldozers

- Remote-controlled excavators

IoT wearables are another milestone towards a safer workplace at mines. Companies are encouraging employees to wear these devices for better communication and handling of emergencies such as a fire in the mine, gas leak, workers' exhaustion levels, and so on.

With fewer accidents, a mining company can experience a rise in productivity and eventually boost its high revenue thanks to control systems.

2. Location and proximity sensors

IoT sensors help avoid accidents in a mine using GPS, radar, RF-locating technologies to detect the proximity of heavy equipment or vehicles. Miners use this information to protect themselves and fellow miners from accidents that could potentially cost lives.

The thing is, a mining worker's safety is directly proportional to the company's profit. When the workers are safe, companies spend less on healthcare and equipment maintenance — saving a fortune that can be used for other business activities.

3. On-demand ventilation systems

Mines often experience contamination as they are filled with deadly gases and hazardous materials. These hurdles can delay work and cause workers to fall sick or even die due to extreme exposure.

The hazardous environments increase the overhead expenses for the mining companies and results in a human loss. Today, with an IoT-based efficient ventilation system, it is possible to detect the quantity of contamination at the exact location and adjust the ventilation accordingly.

Since the ventilators are managed remotely through the internet, the mining company can ensure the safety of the miners underground who can enjoy greater safety benefits without putting themselves in hazardous environments.

4. Equipment sensors for predictive maintenance

IoT sensors are fitted in the mining equipment to provide data about the machinery's health status and operational conditions. The technology helps measure temperature within the mine, contamination levels, fluid levels, the intensity of vibrations, and so on in mining operations.

The equipment sensors deploy predictive maintenance to ensure worker safety and save the cost of repetitive repairs. Because of this support, the mining company can schedule the maintenance of equipment and tools before they break down or malfunction.

Timely repair averts accidents and saves workers from falling sick, injuring themselves, or losing their lives. IoT presents a win-win opportunity for the mining industry and workers.

5. Fleet management and tracking capabilities

IoT improves visibility and control over fleets. Companies can track and manage their trucks and equipment from a central office. Micro-tracking with 5G transmission technology can keep an eye on the fleet's location and monitor it with precision.

The efficient tracking and management of trucks reduce theft instances, wastage, illegal entry, and so on. It also saves money in the mining operations and ensures the safety of workers on the road. For instance, Essar, a company that mines steel, saves 5% on vehicle maintenance and 10% on fuel expenses every year simply by tracking its fleet of 3700 vehicles through IoT.

6. Visualization software

Mines are expansive spaces to plan, navigate, and operate. IoT technologies have made the planning part simple through innovative and accurate tools such as GPS and sensors.

Businesses now access more data derived for Big Data Visualisation as it helps them make informed and confident business strategies, thus making the mining operations successful.

Mine engineers, drill and blast teams, and business managers use IoT-enabled software to create a 3D map of the mine, which they refer to for layout understanding, navigation, operations management, and troubleshooting any emergencies.

A strategic plan with real-time and accurate data and 3D maps makes the mining operations safer, reduces the chances of working in hazardous environments, and be more cost-efficient.

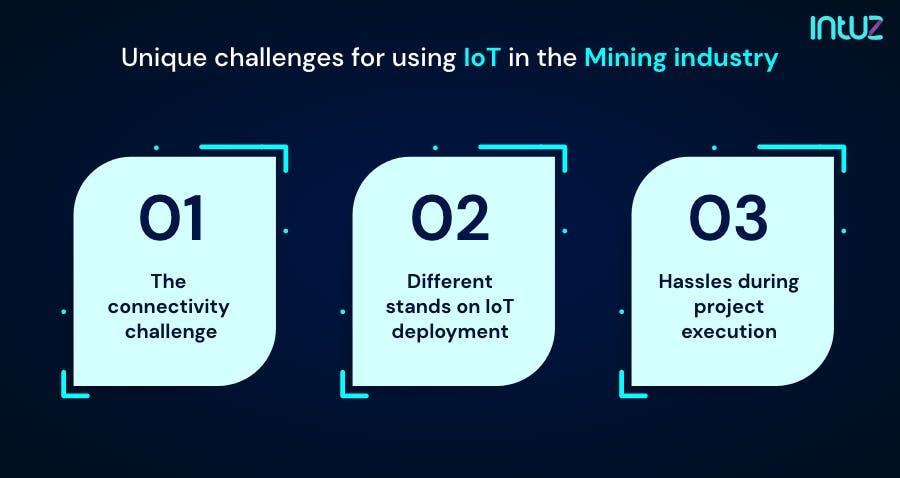

Unique challenges for using IoT in the mining industry

There is no doubt that IoT is at an evolutionary stage, with the mining industry ripe to adopt innovative technology for improving mining operations.

But along with numerous benefits and opportunities, there are several challenges related to IoT that every mining company has to face, including data acquisition, unnecessary costs and mining safety. The following section is all about that:

1. The connectivity challenge in a wireless communication network

Even though IoT provides stable wireless networks in mines, that is still a challenge and may not work as efficiently as possible. For starters, there could be network coverage gaps or variable data performance in different places.

Communication gaps hamper data reliability in mining operations, and they sometimes cause the complete shutdown of the IoT applications. Here is how using cellular IoT can provide some relief:

- Wireless networks fluctuate underground during deep excavations. Cellular networks can help with non-stop connectivity through reboot and reconfiguration.

- The mining company can install multiple antennas from different directions to deal with the network issues in heavy vehicles on the road.

This communication gap due to the network seems more challenging on crucial projects that need complete data accuracy and also do not increase unnecessary costs.

2. Different stands on IoT deployment in the mining industry

Even though there is a growing reliance on using IoT by all mining companies, as this is the present and future of the mining operations, there are two sides of the coin.

The truth is mining companies are divided on the deployment of the Internet of Things and are still hesitant to replace the traditional mining methodologies.

On the one hand, more data about the industry shows the positive impact of IoT on the mining industry. Investment in R&D is at an all-time high.

The mining industry has been progressing at a very healthy rate, with more and more companies increasingly deploying IoT systems to improve business efficiency.

Another set of mining industry leaders believe otherwise. They are not in support of investing in IoT because of unstable industry parameters and prevailing market fluctuations.

But they do not realize that the mining industry needs to keep investing in the R&D of the IoT technology. Market trends will keep fluctuating, but transformation for better technology will give lifetime returns for any mining companies.

3. Hassles during project execution

There are operational challenges as well that a business has to deal with to implement an IoT-based system. Mining companies often require mining at different remote locations that might pose a problem, especially if more data about the operation is not available. This proves too costly for the business and also puts the employees at risk.

Enhance Mine Safety and Efficiency with Custom IoT Integration!

Explore SolutionsOver to you

IoT has made the mining industry safe for workers, productive, and efficient for businesses. Sensors, automation, self-driving vehicles, real-time data collection and analysis, predictive analytics, and similar innovations of the Internet of Things have changed the traditional mining industry.

If you are a mining company looking to drive progress and reduce unnecessary expenses with scalable IoT solutions, you have come to the right place for our expert developers to build you a system that causes profitable improvement in the way you operate.

Book a Free 45-minute Consultation with Our IoT Experts Today! Get a free customized roadmap and strategies to leverage IoT to streamline and automate your mining operation.